Perfect Product

Perfect Product

End Results Matter

Then end product is how customers identify with your product and ultimately your brand. For many years it was purely yield that dictated the strength of the business but the market has evolved to a point where supply has been established and quality is what defines your brand.

Versatility

Versatility

Thoughtful Design

+

Versatility

Each strain has many different attributes that make it unique. The same goes for its curing process. When designing a dry cure room it’s important to have flexibility in the design to allow for various racking options from hang drying, to bakers trays to large mesh racks.

Air Flow Design

Air Flow Design

Even Air Flow

=

Consistent Product Quality

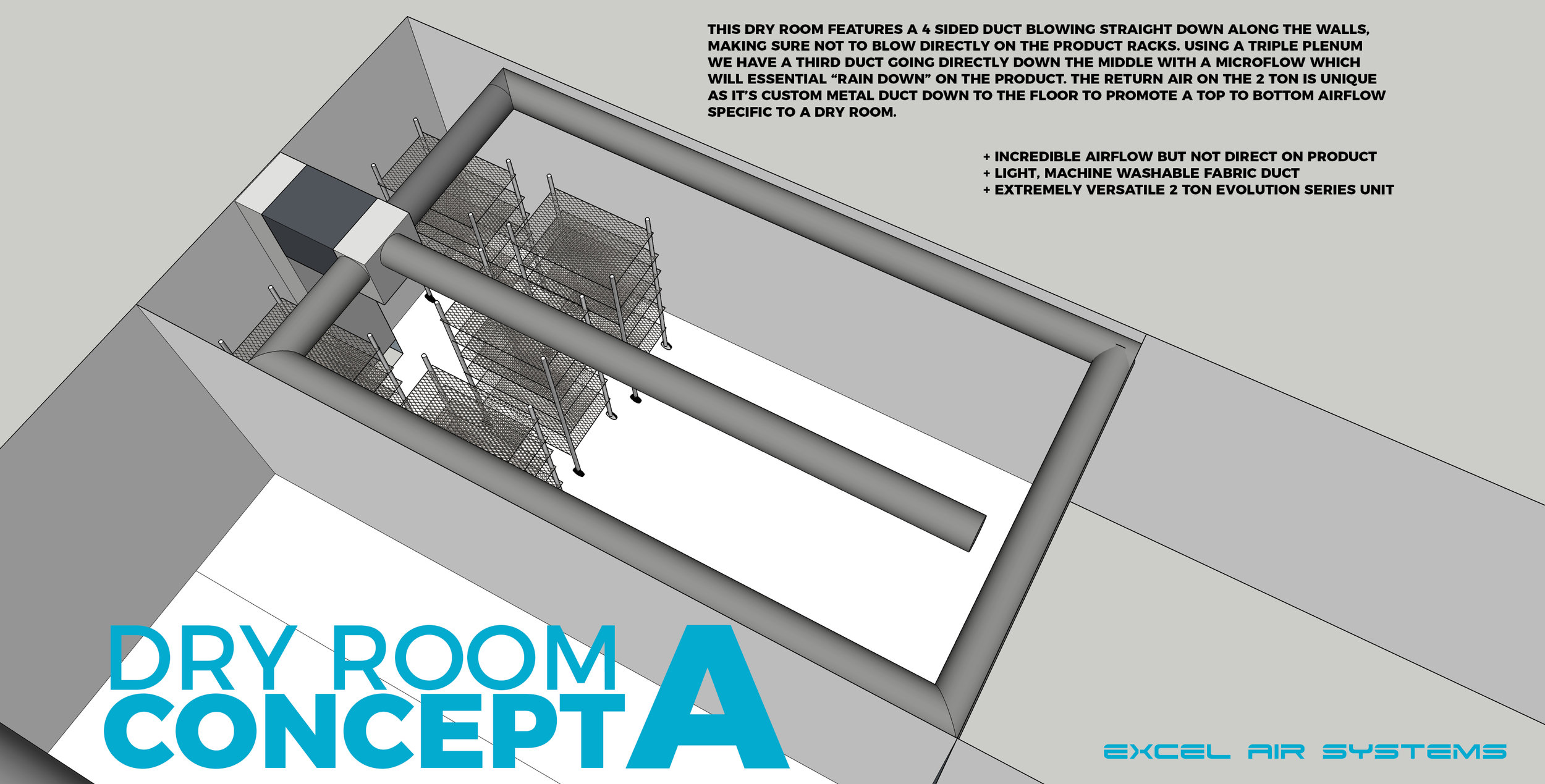

It’s tremendously important to design for proper air flow across the entire room. It’s even more important to achieve this without direct high velocity air hitting the product as this will lead to uneven drying times. We design drying rooms specific to the type of racking, size of space and amount of bud that will be in the space at any given time.

The process

We start out with the general room dimensions, amount of wet product that would be in the space at any given time, type of racking/hanging method and required dry time. With these questions answered we then select the appropriate sized system. We find more often than not our Evolution Series 2 Ton “CUBE” is ideal due to it’s ability to Air Condition, Mass Dehumidify and Air Filtering capabilities. It’s also our most compact unit so fitting it into tight spaces is never an issue. The last and arguably the most important step is designing the air flow as this will determine how even we can dry and cure the product. We try and provide complex solutions that we have made extremely simple to roll out. All of our ducting is engineered to exact standards but refined in a way to make installation and maintenance easy and efficient.

Humidity Control

Humidity Control

Dry to perfection

Removing excess moisture from the inside out is the key to the entire process. In combination with mass dehumidification, temperature and air flow we’re able to regulate levels that allow for your product to smell, taste and burn as clean as possible.

Slow And Steady

There are certainly many different ways to bring humidity within the bud down to the perfect level. We’ve found that most of our clients look to slowly walk these levels down over 7-28 days. Generally a standard “dry” time of 7-14 days is suitable for most product where “curing” time generally extends beyond 2 weeks slowing the process further to ensure many other attributes such as trichromes, terpines and appearance are as ideal as possible. Curing will also help extend the shelf life of the product.

Inspiration

Inspiration

Always evolving

+

Building on experience

We’ve designed been designing flower rooms, veg rooms, mother rooms and dry rooms for over 13 years and through these experiences have amassed incredible knowledge. Take a look at some of our concepts.

S

S

Check out our units